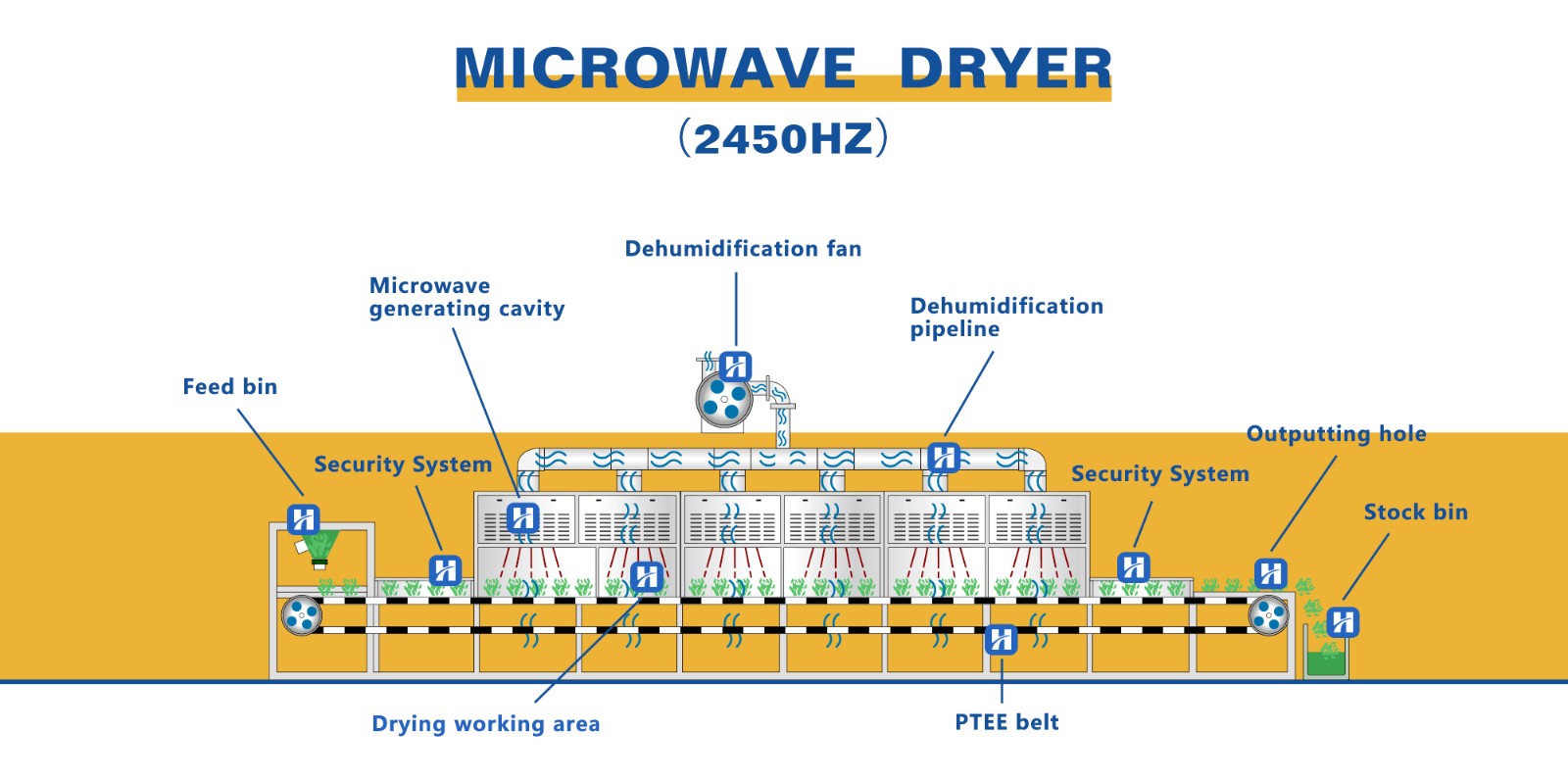

Industrial Tunnel Continuous Microwave Drying Machine

Application of industrial microwave drying machine

1. Drying and sterilization of dog food, cat food and cat litter

2. Drying nuts, cashews, pistachios, cocoa beans and coffee beans.

3. Drying tea leaves, spices, peppers, flowers and seafood.

4. Drying fruits, grapefruit peels and coconut shells.

5. Drying mealworms, black soldier flies, insects, etc.

Industrial Tunnel Continuous Microwave Drying Machine

Microwaves are electromagnetic waves with frequencies ranging from 300 MHz to 300,000 trillion Hz. Water molecules in the material of the heated medium are polar molecules. Under the influence of rapidly changing high-frequency electromagnetic fields, the polarity orientation of materials will change with the change in field, causing movement and the effect of mutual friction of molecules. At this time, the microwave field energy is converted into thermal energy in the medium, which increases the temperature of the material and causes a series of thermalization and expansion processes to achieve the purpose of microwave heating and drying.

Heats up quickly:

A conventional heater enters the inside from the outside of the heated object;And microwave heating makes what is heated heated,a process that does not need thermal conduction,microwaves penetrate into and out of the object from all sides at the same time, allowing the object to achieve uniform heating of antibacterials in a very short time,has greatly reduced the time dry sterilization,increase release.

Uniform heating:

Regular heating, to increase the heating rate, it is necessary to increase the heating temperature, which easily leads to the formation of external coke, an internal immature phenomenon. When heated by microwaves, body parts are usually uniformly penetrated into electromagnetic waves,generating heat, the uniformity is greatly improved.

Energy Saving:

In microwave heating, microwave waves can only be absorbed by heated objects to heat them, heating the indoor air and related containers are not heated, so the thermal efficiency is extremely high, and the production environment has been greatly improved. Electricity supply by 30% compared with far infrared heating .

Cryogenic sterilization is not contaminated:

Microblocks themselves do not contaminate food, while the microwave thermal effect of dual antiseptic can kill bacteria at lower temperatures, it is a heat sterilization method that maintains more nutrients in food.

Selective heating:

Microwave waves affect different substances of different properties, since water molecules absorb microwave waves best, so high humidity absorbs more microwave waves than those parts that have less moisture, which is typical when choosing heat. Dry wood, paper, etc. Used for uniform heating and uniform drying.

Good bactericidal effect:

Using microwave sterilization at 70 ℃ you can kill all this, E. coli at 80-90 ℃ the total number of bacteria is significantly reduced, you need 2-8 minutes. Fast, short term, thus preserving nutrients in food, traditional taste.

Easy to manage, technologically advanced:

Compared with the conventional method, the equipment turns on and operates; no thermal inertia, flexible and convenient to operate; microwave energy adjustment, transmission speed adjustment. In microwave heating antibacterial drying, no waste water, exhaust gas, slag, radiation, is a safe and new technology .

Application of Microwave Dryer